Design of brushless DC motors

Click on any of the sections below to expand its content.

Our design tools for brushless DC motors We have developed a software for design of brushless DC motors with fractional number of slots per pole and phase, and with a stator winding consisting of a set of concentric coils.

Input data

1) input DC voltage; 2) nominal motor torque; 3) nominal speed in rpm; 4) number of phases.

Calculation steps

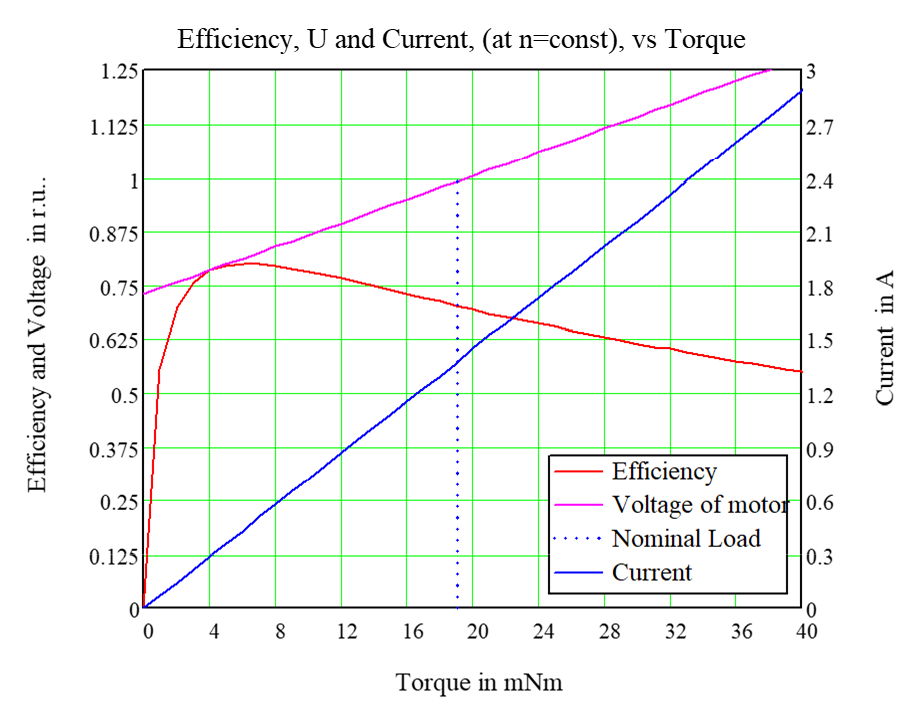

Performance characteristics

Below you will find typical performance characteristics for one of our designs: This data corresponds to experiments.

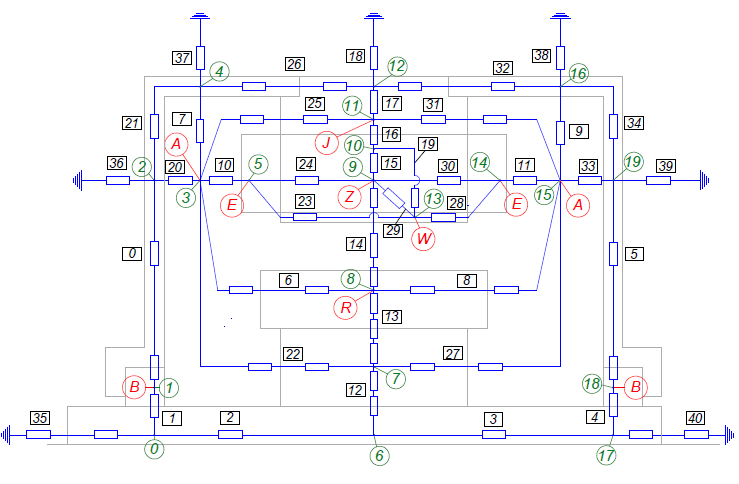

Thermal analysis

Thermal calculation of the motor is based on a detailed equivalent thermal scheme of the motor and a graph theory:

Capabilities of our design software Our design software enables designing of brushless DC motors either with concentric windings, or with a partial number of slots per phase per pole or with distributed windings.

We are capable of designing a single brushless DC motor as well as a series of brushless DC motors.

We can perform a full finite element analysis of a brushless DC motor.

We can perform calculation of operation modes of a brushless DC motor for different types of control including vector control.

We can perform a full thermomechanical analysis of components of a motor, such as a shaft, a housing, bearing shields and a stator winding including forces acting on the winding during operation.

We can develop a full structure of a brushless DC motor with an outline drawing or a general drawing. We can provide drawings of main components of a brushless DC motor corresponding to specific requirements of a customer.

We can design brushless DC motors for any of the following implementations: IP54, IP55 or IP23.

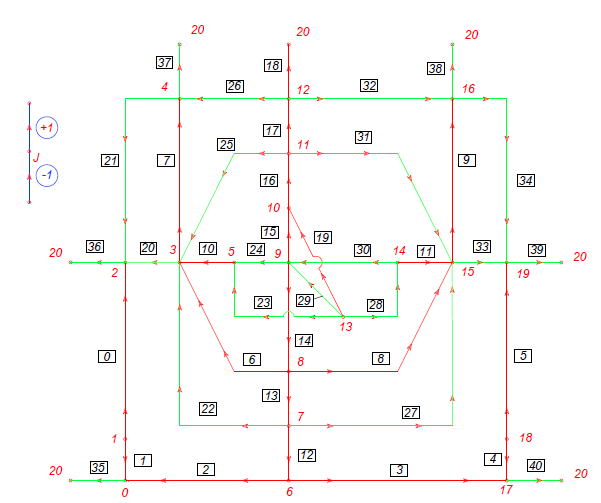

Based on our patent US 8253295 “Schemes of interchangeable windings of electrical machines” we can design a brushless DC motor with a sinusoidal distribution of MMF in the air-gap and a double-layer or a triple-layer stator winding not having intersections in the end-winding region. Such windings are easier for manufacturing and more suitable for pulling into the slots. This leads to better reliability of the windings and a higher filling factor for the stator slots. Brushless DC motors with a sinusoidal distribution of MMF in the air-gap have lower core losses and, consequently, a higher efficiency and produce less noise.