Special services for asynchronous machines

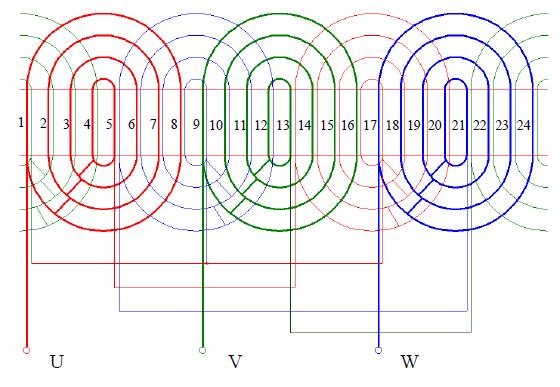

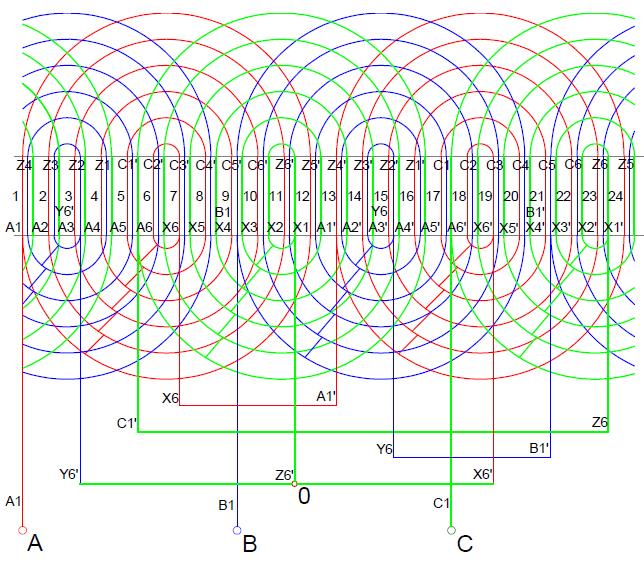

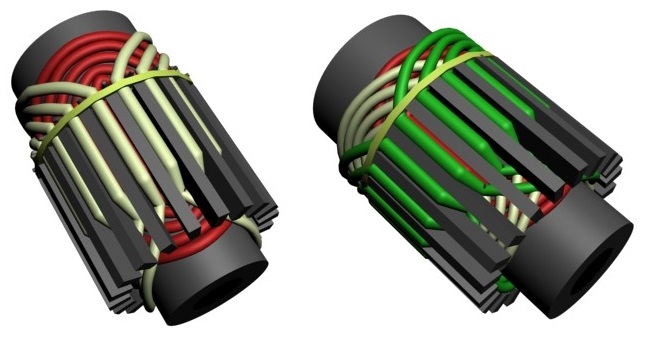

Based on our patent US 8253295 “Schemes of interchangeable windings of electrical machines”, we can design asynchronous motors with a sinusoidal distribution of MMF in the air gap and with a stator winding having two or three layers. Such windings have no intersection in the end winding zone. Therefore they are especially suitable for automated insertion. This winding structure prevents damage to insulation and provides easy assembly and reliable operation of the whole motor. In addition to that, a higher filling factor could be achieved in the stator slots.

Asynchronous motors with a sinusoidal distribution of MMF have lower losses, higher efficiency, low noise. Such motors are particularly suitable for high precision electrical drives.

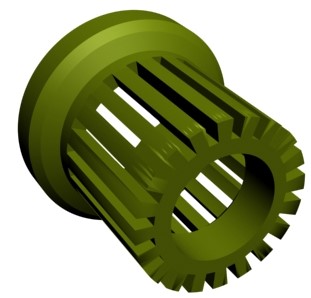

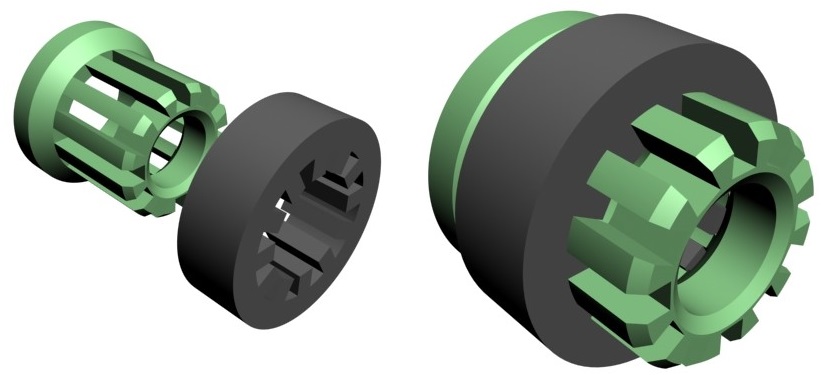

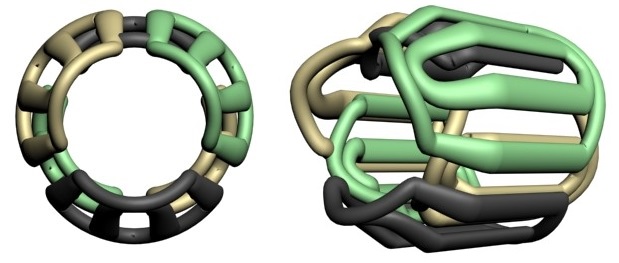

Based on our patent US 7913375 “Method for making windings for electrical machines and winding obtained by

Manufactured windings with 120 deg phase sones